Thermal Design & CFD

We have 10+ years of experience in the following areas of Thermal Design and CFD in Electronics :

Thermal Design :

- Product Design (Mechanical, Embedded, and Electronics design)

- TOTAL Thermal Management of Electronics

- Design / analysis & supply of Heat sinks, DC Fans, heat pipes, TECs

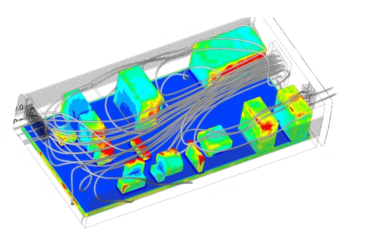

- Thermal (CFD) analysis of electronics

- Test & measurement (sensors, anemometers, wind tunnels)

- Fabrication of prototypes, conventional & CNC machining

Electronics Cooling (CFD) :

Military :

Different types of Modules and Chassis :

- Forced Air Cooled

- Conduction cooled

- Liquid Cooled (exploratory studies)

Telecom

- BTS

- ATCA

- Inverter (power backup)

Capabilities :

Thermal Simulation :

- Estimate junction/case Temperature and comment on thermal safety of the devices

- Determination of fan operating point

- Visualization of flow field – dead zones, heat sink bypass, etc

Optimization :

- Heat sink – selection / custom design

- Selection of fans

- Selection and design air filters / vents etc

Mechanical Design of Card modules and Chassis

- ANSI/VITA standards – for military applications

- NEBS, NEMA and Euro standards – for telecom applications

Electronics Cooling :

- Intelligent fan tray

- CPU fan coolers

- DC brushless Fans & blowers

- Heat sinks (Al, Cu, extrusions, pin fins, heat pipes, vapor chamber or custom)

- Heat pipes

- Liquid cooling

- TECs & TEGs

- Test & measurement

- PCB fab, MC PCBs, Flex PCBs

Fabrication Support :

- Thermal management products

Heat sinks (Al, Cu, extrusions, pin fins, heat pipes, vapor chamber or any other custom requirement), heat sink mounting hardware. - Design and manufacturing of sheet metal and machined enclosures and other customized parts.

- Multi-layer PCB fab: Upto 16 layers and Flex PCBs.

- Metal Core PCBs for high density power conversion, motor control, flat panel displays, lighting, automotive and solar applications.

- Plastic injection molding & die casting.

- CNC Turing, Pressing and Radial Drilling

Major Industries Verticals Supported :

- Automotive

- Government (Defence, Derospace, Nuclear)

- Telecom, computer, medical electronics, white goods

- Engineering

Methodology/Process Followed :

- Inputs from customer / datasheets : Such as ambient conditions, power dissipation, board details (number of layers, thermal vias etc), device part numbers/ datasheets, material specification etc.

- Processing IDF files – Board layout and devices are modeled by importing and cleaning the IDF files.

- Modeling chassis / enclosures / covers

- If 3D CAD is available, the data is converted into formats/shapes that are usable in the analysis tool.

- Else, the model is constructed based on the specifications.

- Compact thermal models – DELPHI, 2R models that are available from the device vendor are incorporated in the board

- Improves the accuracy of junction temperature prediction.

- Information from datasheets can be also used to construct these network models.

- Meshing – number of cells and the sizing is decided based on the thermal / flow requirements.

- Mesh in-dependency checks are carried out to arrive optimum mesh density.

- Application of boundary conditions and numerical simulation of the model.

- Physics based selection of boundary conditions and numerical models

- Simulation results are verified by appropriate hand calculations.

- Result review, documentation and recommendation of design improvements

- Results are thoroughly analyzed to understand thermal bottlenecks, flow distribution etc.

- Contour / vector plots, quantitative data (temperature, flow rate etc) are documented

- Design improvements are suggested based on these observations

- Based on customer comments, the design changes implemented and optimization is carried out till the specifications are met.

Partial List of our customers : Thermal Design & Electronics CFD :

- Automotive : Robert Bosch, Delphi, Visteon

- Electronics : Juniper Networks, EATON, CISCO, O/E/N, Amararaja Power, Aricent Group, Tejas Networks, Rancore Technologies

- Engineering : Infosys, HP, HCL, WIPRO, TCS, Lukup, Mindteck, Mistral, ProcSys, CoreEL, Aricent, CSG, Data Patterns, Honeywell, Reliance Info

- Govt : BEL, MTRDC, CDOT, DARE, ISAC, LEOS, LRDE, SAMEER, IGCAR

Tool Experience :

- FEA – Ansys, Midas NFX

- CFD – FloTHERM, Icepak, Fluent, Answer