Simcenter 3D

Address complex engineering challenges by enhancing simulation efficiency

Simcenter 3D is a comprehensive, fully-integrated CAE solution for complex, multidisciplinary product performance engineering. The software delivers revolutionary improvements in simulation efficiency. With advanced 3D modeling capabilities and simulation solvers that cover a comprehensive range of physics, Simcenter 3D helps you gain better insight into your product’s overall performance. This is achieved through a fully integrated and managed, yet open environment, where you perform all CAE pre-and-postprocessing on CAD data from any source for Simcenter and third-party solvers. Tied to the digital thread, engineers and analysts can collaborate on a platform that accommodates all aspects of functional performance.

Simcenter 3D Solution Guide

Addressing complex engineering challenges by enhancing simulation efficiency

Learn why Simcenter 3D is the most comprehensive, fully integrated CAE solution on the market today.

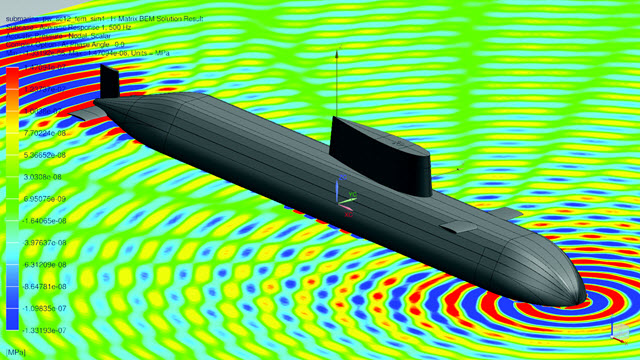

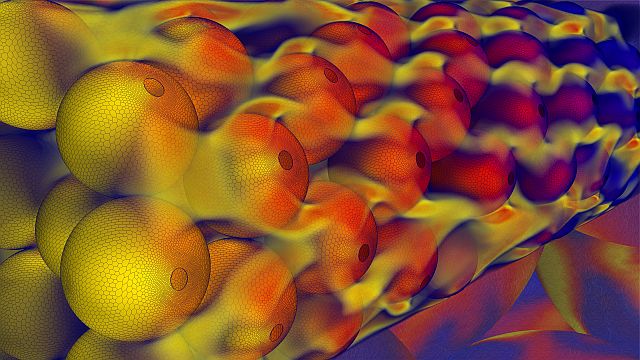

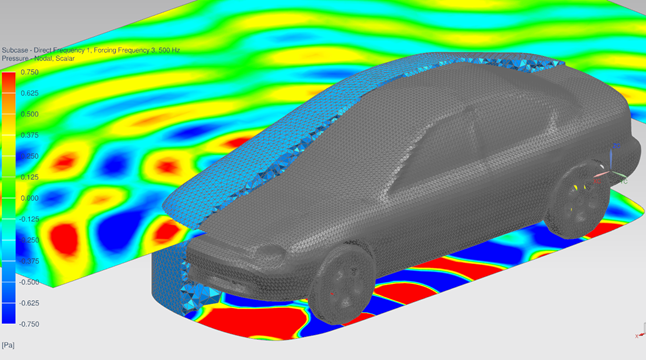

Acoustic Simulation

Simcenter acoustic software offers interior and exterior acoustic simulation analysis within an integrated solution that helps you make informed decisions during the early design stages so you can optimize your product’s acoustic performance. A unified and scalable modeling environment combined with efficient solvers and easy-to-interpret visualization capabilities enable you to quickly gain insight into the acoustic performance of your product.

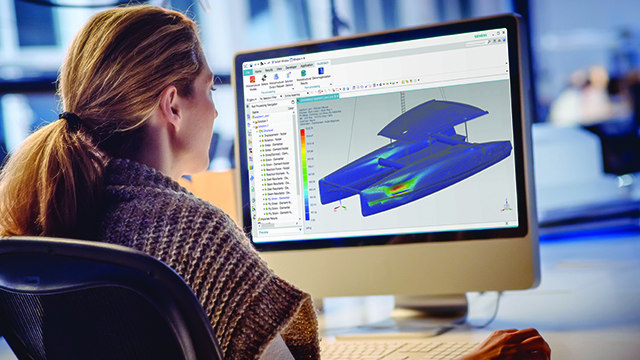

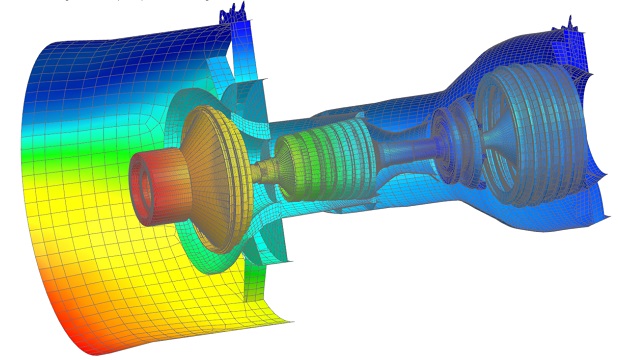

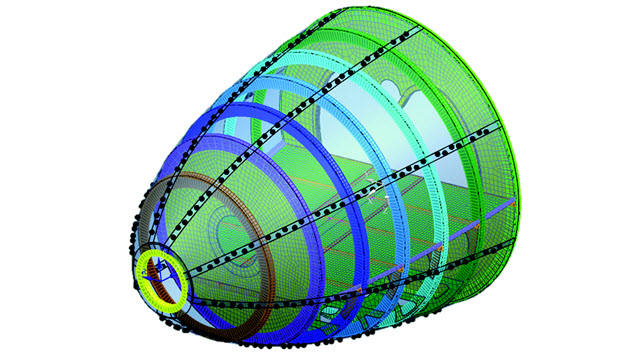

Aerostructures Simulation

Simcenter can help you meet shorter timelines and reduce structural analysis costs with the ability to perform end-to-end aerostructure assessment in a fully integrated environment.

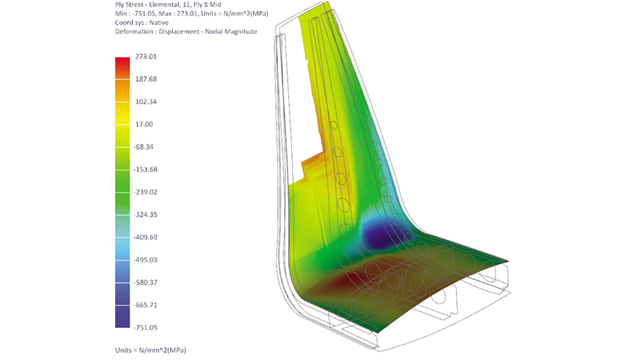

Composites

In the quest to make products lighter yet stronger, manufacturers are increasing their use of composite materials. Simcenter is at the leading edge of composites analysis through continuous development of material models and element types. Simcenter speeds the entire process for simulating laminate composite materials through a seamless connection to composites design, accurate solvers and comprehensive post-processing.

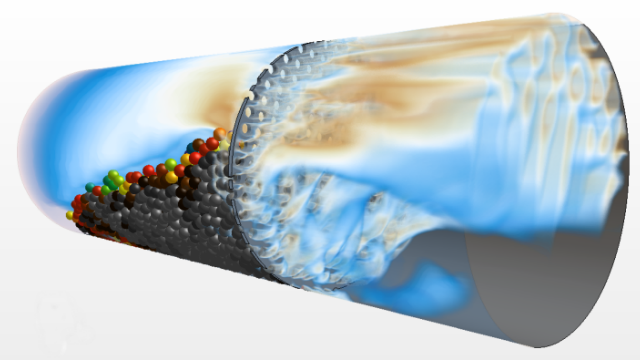

Computational fluid dynamics (CFD) simulation

Simcenter provides industry leading computational fluid dynamics (CFD) software for fast, accurate CFD simulation of almost any engineering problem that involves the flow of liquids, gases (or a combination of both), together with all of the associated physics.

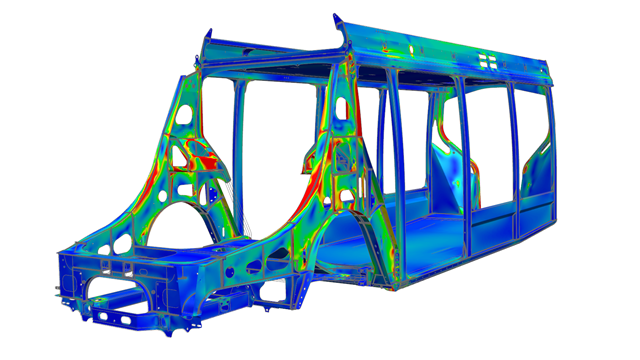

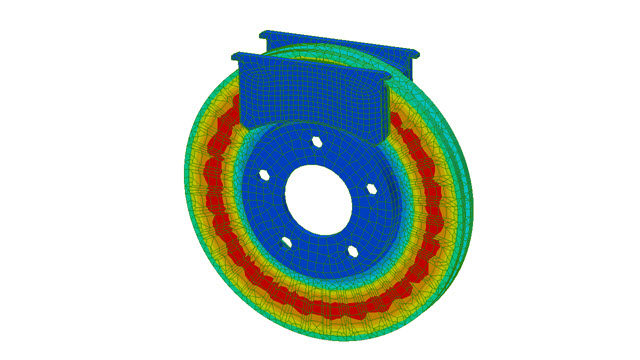

Durability Simulation and fatigue analysis

Simcenter gives you access to state-of-the art durability software methods that enable you to perform fatigue analysis and fatigue life prediction analyses quickly and accurately accounting for realistic loading conditions.

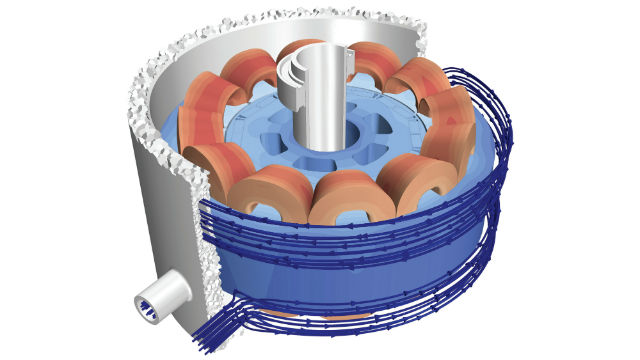

Electromagnetic Simulations

Simcenter includes distinct low and high-frequency electromagnetic simulation capabilities for the unique demands in each domain. Expand your insight into the performance of electromechanical components, energy conversion, the design and siting of antennas, electromagnetic compatibility (EMC) and electromagnetic interference (EMI).

Motion Simulation

Motion simulation helps you predict the reaction forces, torques, velocities, acceleration and more for mechanical and mechatronic systems. Improve mechanism performance using an accurate and robust 3D multibody dynamic simulation approach.

Multiphysics Simulation

Complex industrial problems require solutions that span a multitude of physical phenomena, which often can only be solved using simulation techniques that cross several engineering disciplines.

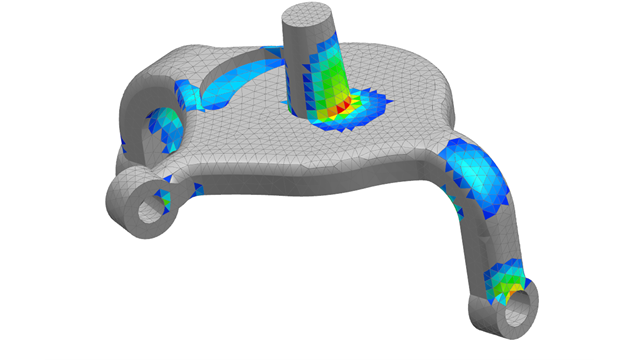

Structural Analysis

Understanding how a component or product assembly reacts under stress or vibration is critical in any industry. However, as products and materials become increasingly complex, engineers need tools that go beyond linear-statics analyses. Simcenter provides the structural analysis software you need to simulate a wide range of applications all within a single user environment.

Structural Dynamics Simulation

Simcenter offers a comprehensive solution to understand, analyze and improve the response when a system is subjected to dynamic loading.

Thermal Simulation

Simcenter includes comprehensive, best-in-class thermal simulation capabilities that can help you to understand the thermal characteristics of your product and subsequently tailor your thermal management solution for optimal performance.

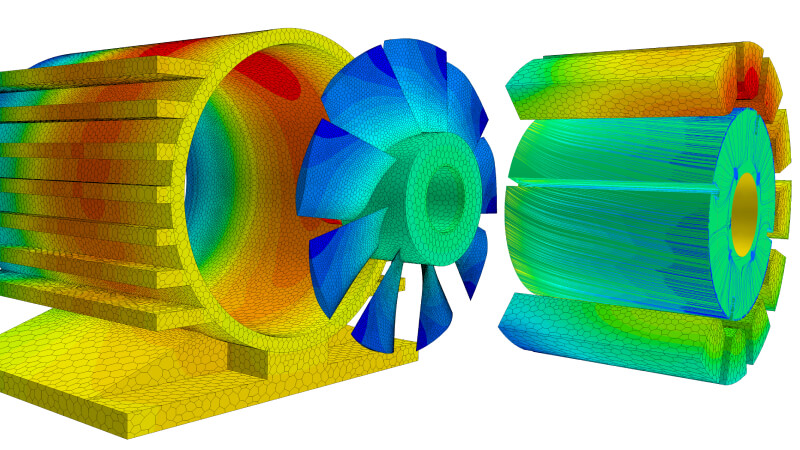

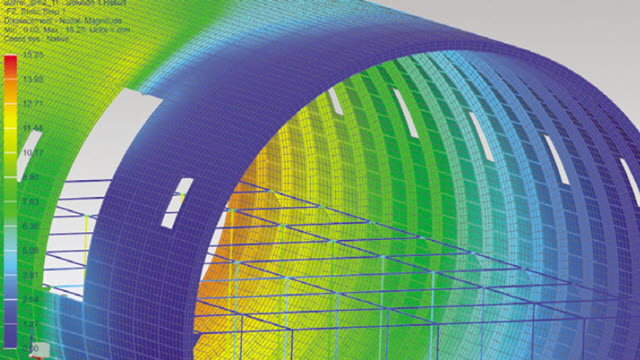

Meshing

Efficiently mesh your models using extensive modeling functions for automatic and manual mesh generation of 1D, 2D and 3D elements in addition to numerous techniques for the application of loads and boundary conditions. User-defined geometry edits, mesh and boundary conditions are all associated to the base design, which means when the base design geometry changes, you can rapidly update your model. This approach greatly reduces downstream modeling time, which results in huge time savings across a project’s many design-analysis iterations.

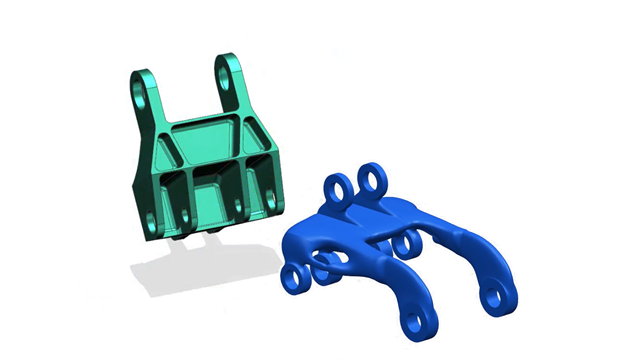

Optimization

How can I reduce material in a component or change its properties while ensuring it continues to meet performance targets? Simcenter delivers engineering optimization techniques that can help you answer these this question by systematically searching for the best design that satisfies certain criteria. Reduce component weight or find the right combination of parameters to improve product performance through comprehensive topology, geometry, and parameter optimization capabilities.

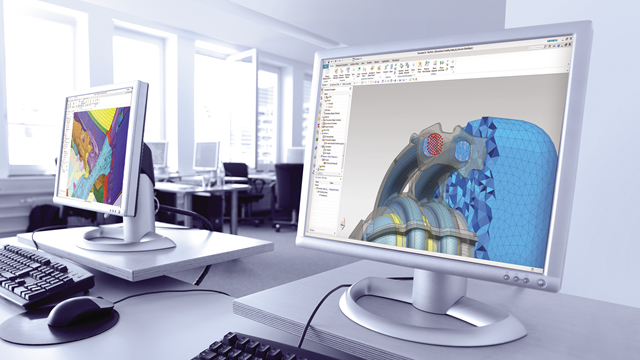

Pre / Postprocessing

Reduce the time you spend preparing analysis models, and spend more time evaluating results. Quickly move from multi-CAD geometry data to a complete, run-ready analysis model using unique tools for CAE geometry editing, comprehensive meshing, FE assembly management, multi-CAE solver environments, and fast simulation results post processing and reporting.

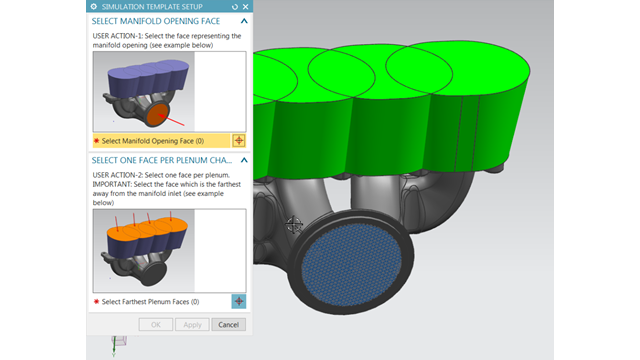

Simulation Automation & Scalability

As companies increase their reliance on simulation, they are seeking ways to speed-up the analysis process and increase simulation throughput. One way to increase simulation throughput is to capture repetitive CAE processes, standardize them, and then automate them. Simcenter allows you to capture the expertise of senior analysts and make it available for junior engineers in your organization to use in the form of wizards or templates.

Featured Customer Success

Academic Motorsports Club Zurich

Academic race car manufacturer designs record-breaking race cars from scratch within a few months

AMZ uses NX and Simcenter software to optimize race car designs and maintain leadership in Formula Student competitions.

On-Demand Webinar | 40 minutes

Developing industrial electric motor to requirement through simulation and testing

Industrial electric motor design, simulation, testing and integration